Xin Cang Tai SMT laser steel net special steel 304 h, 304 h - TA, 304 the hta - SR2 non-magnetic, no magnetic steel imported from Japan, used in SMT laser steel net, can half etching 304 h - TA thickness of 0.03 mm to 0.5 mm, width 280 mm to 600 mm all have inventory, can cut plate according to the customer request processing

To update:2018-01-11

Message

Contact

Share to:

The sus304h-sr2 SMT laser steel wire mesh:

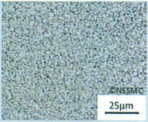

The material hardness is 1/2H, 3/4h, the surface is flat, eliminate the internal stress, and the semi-etching is reduced to flat. Metal crystal tissue 2-5um

SUS301SE1 SMT laser steel net special steel sheet parameters:

|

The name of the |

SUS304 H-SR2 |

NSSMC-NAR.301L-SE1 |

|

|

Quite JIS specifications |

SUS304 |

SUS301L |

|

|

Metal set of machine |

|

|

|

|

Average crystal size |

2~5μm |

~2μm |

|

|

Product features |

flatness |

Very good |

Very good |

|

bending |

Very good |

Very good |

|

|

Surface smoothness |

good |

Very good |

|

|

processability |

good |

Very good |

|

|

The main purpose |

Precision machining |

High precision, high density processing |

|

|

The name of the |

SUS304 H-SR2 |

NSSMC-NAR.301L-SE1 |

SUS304 H-CSP H |

|

Quite JIS specifications |

SUS304 |

SUS301L |

SUS304 H |

|

0.2% endurance (MPa) |

1059 |

996 |

≥880 |

|

Tensile strength (MPa) |

1174 |

1177 |

≥1130 |

|

Stretch (%) |

10 |

33 |

- |

|

Hardness (HV) |

401 |

397 |

≥370 |

|

The thickness of the |

0.08~0.40mm |

0.08~0.25mm |

- |

|

Board of |

≤600mm |

≤600mm |

- |

|

appearance |

sheet |

sheet |

sheet |

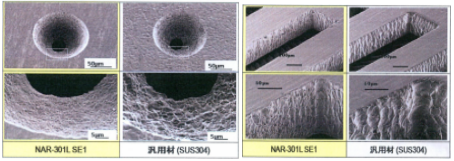

Product appearance fine-grain, machining surface, smoothness comparison chart

SMT laser steel net special steel feature:

1, flat, strong and elastic.

2, laser stencil stencil is commonly used in SMT industry, it greatly improve the making craft of computer automatic control degree, laser cutting machine driven directly by computer equipment, light metal plate cutting, so that greatly reduces the working procedure for man-made error, in the process of the principle of laser cutting machine itself also ensures high precision steel net.

3,The laser cutting open is inverted cone-shaped, matching characteristic polishing and finishing processing, making the steel mesh stripping performance better!

SMT laser steel mesh application:

Strong magnetic steel plate with hardness above 550 degrees for magnetic treatment and blade. High end etch stainless steel, 304 301 316 and 304-sr stainless steel, precision stamping parts stainless steel. , 304, 301, 316 and 304 - SR non-magnetic stainless steel grades, such as etching nameplate special stainless steel, 304, 8 k, 12 k mirror fabrics, pot piece special steel piece, smooth, good strength, strong elasticity. Designed for metal stamping, metal etching products, etching nameplate products, SMT stencil, laser steel net, pot, loudspeaker, components, special separated coiled plate can be brushed, stainless steel filter, surface treatment, etc.

SMT laser steel mesh inspection:

SMT laser steel mesh product packaging and transportation:

1, the finished product is wrapped in paper, and the bottom is put on the wooden cover to avoid the distortion.

Be careful not to touch moisture, dust, oil, lubricating oil, dust and so on, lest rust or welding be less corrosive.

3, because of high precision stainless steel products with the requirements of physical properties and chemical properties, in the storage and transportation in order to prevent damage, stainless steel products packaging shall be maintained in good condition, and product should be fixed well in order to avoid a collision deformation and corrosion.

Shenzhen Xin Cang Tai technology co., LTD, based on years of experience in technology, master the ultra-thin stainless steel belt for high precision strip thickness of 0.02 mm or less, to stress series, can satisfy the terminal for stamping for etching or deformation after heating. Mastered the demagnetization process of austenitic stainless steel more state, according to customer requirements in the production of low magnetic, weak magnetic hard stainless steel belt, to meet the needs of downstream customers.