Brass is an alloy of copper and zinc because of the color yellow. With high strength and plasticity, it can withstand cold, hot pressure and corrosion cracking. The brass has good mechanical properties, thermal state of plasticity is good, under the cold plastic can also, good cutting, brazing and welding, corrosion resistant, but easy to produce corrosion cracking.

To update:2017-05-26

Message

Contact

Share to:

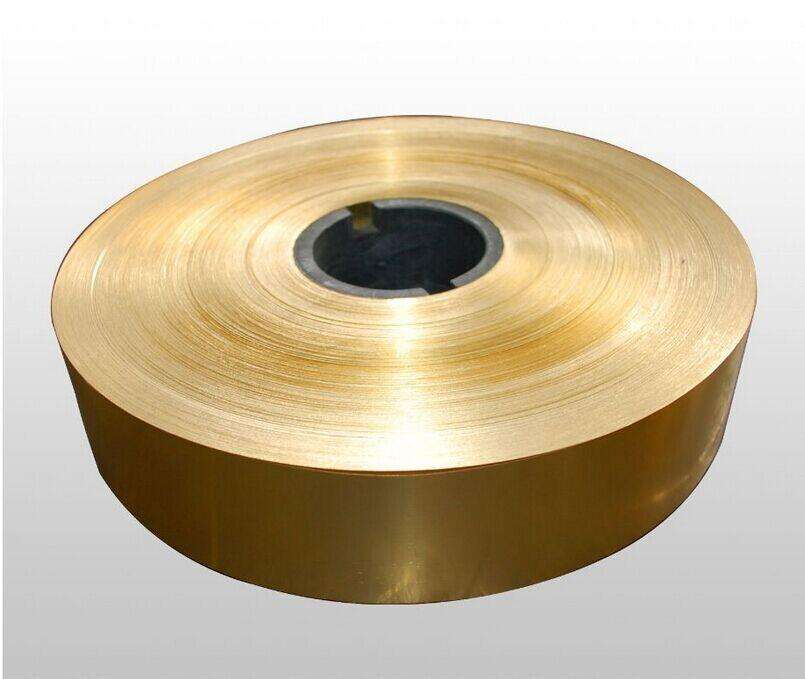

Precision brass band introduction

Brass is an alloy of copper and zinc because of the color yellow. With high strength and plasticity, it can withstand cold, hot pressure and corrosion cracking. The brass has good mechanical properties, thermal state of plasticity is good, under the cold plastic can also, good cutting, brazing and welding, corrosion resistant, but easy to produce corrosion cracking. In addition, the price of this kind of brass is cheap, and it is widely used as an ordinary brass. Used for hardware, daily necessities, small springs, screws, rivets, mechanical parts, electronic components, etc.

Introduction of brass band parameters

|

Processing copper chemical composition (GB/T 14954-1994) |

|||||||||

|

H65 brass band chemical / % |

|||||||||

|

铜Cu |

锌zn |

铅Pb |

硼P |

铁Fe |

铍Sb |

铋Bi |

- |

impurities |

other |

|

63.5~68 |

allowance |

0.03 |

0.01 |

0.10 |

0.005 |

0.002 |

- |

0.3 |

- |

-

Thickness: 0.05 to 0.8 mm

Width: 5 ~ 400mm

Length: winding

Tensile strength: 390 ~ 530

Elongation: greater than or equal to 13

Hardness: 105 ~ 175HV

Heat treatment specification: hot working temperature of 640 ~ 780 ℃; Annealing temperature is 600 ~ 650 ℃; Eliminate the internal stress of low temperature annealing temperature is 285 ℃.

Remark:

The required specification is less than the dimension (section).

Special specifications need to be customized in advance;

The price of materials is floating, the price is for reference only, and the price is subject to the real time quotation.